Flame Resistant vs Flame Retardant Cables: What Is The Difference?

Flame-resistant and flame-retardant cables are designed to improve safety in environments with a fire risk. However, the purpose of these cables is very different. Let's look into it in more detail.

Flame resistant cables

Flame-resistant (or fire-resistant) cables are designed to maintain circuit integrity and continue operating for a designated period under direct fire conditions. These cables can withstand the fire without losing their functionality. As a result, emergency systems such as alarms, sprinklers, and lighting can continue to operate during the fire. Flame-resistant cables can work in a fire for either an hour or two. UL 2196 is the leading standard for fire-resistive cables. They are also known as circuit integrity (CI) cables.

- Flame-resistant cables are made with materials that can withstand high temperatures. Examples of such materials are mica, glass, and ceramic.

Flame-resistant cables are used in emergency and critical systems, such as:

- Emergency lighting

- Fire alarm systems (as regulated by NEC 760 and NFPA 72).

- Evacuation communication systems (as discussed in NEC 800).

Flame retardant cables

Flame retardant cables are designed to resist fire spread into a new area. These cables inhibit the flame from propagating along the cable length and reduce the emission of smoke and toxic gasses in the event of a fire. Flame-retardant properties of cables are regulated by UL 94.

- They are made with materials designed to self-extinguish once the source of the fire is removed. The outer materials of these cables are treated with flame-retardant chemicals. This can be flame-retardant PVC, LSZH components, TPU, FRPE, FRPP, and others. Flame retardancy in cable

- Cables with flame-retardant properties are used where reducing the spread of fire is essential, but maintaining circuit integrity under fire is not critical. This includes plenum and riser applications in residential and office buildings.

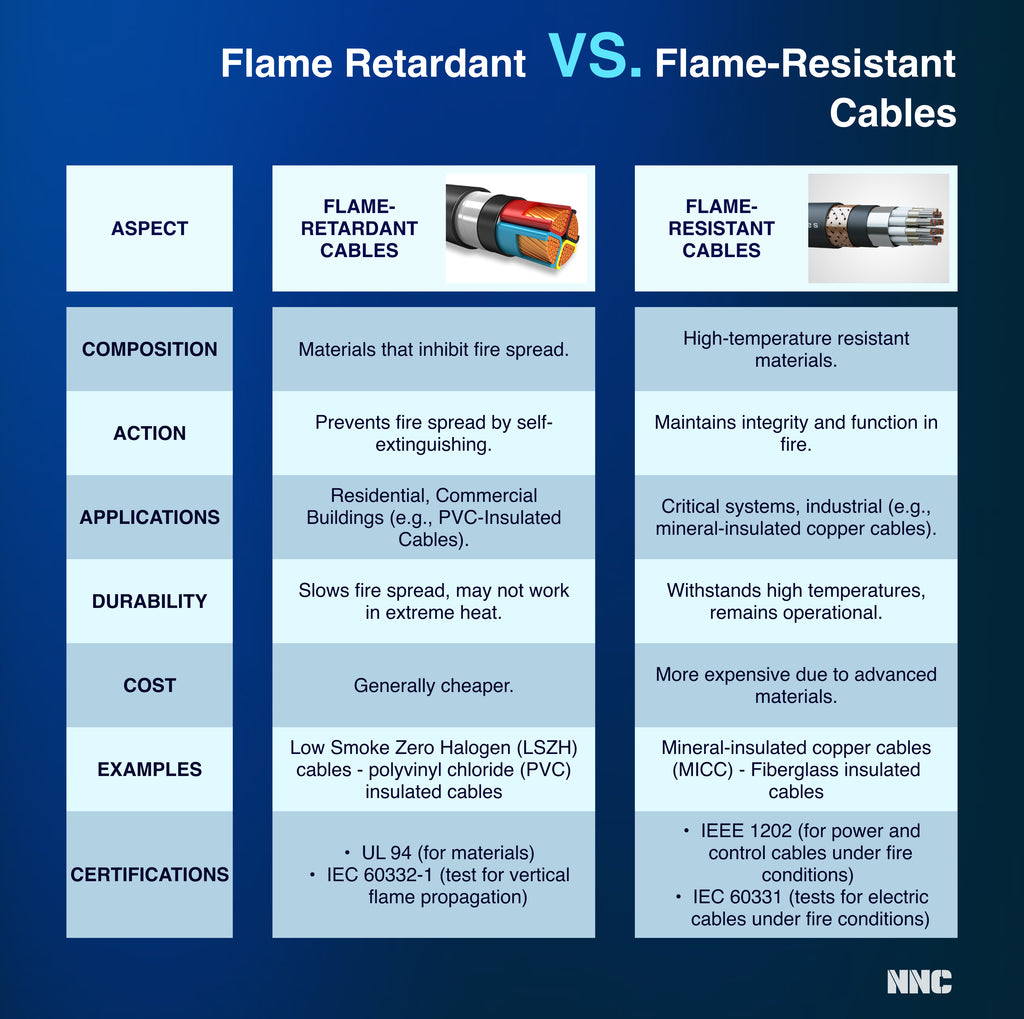

Key differences

- Flame-resistant cables are designed to continue operating in a fire, whereas flame-retardant cables are designed to prevent the spread of fire.

- Flame resistant cables use materials that can withstand high temperatures without losing functionality. Flame retardant cables use materials treated to self-extinguish once the fire source is removed (PVC, TPU, LSZH, etc).

- Flame-resistant cables are critical for safety systems that must operate during a fire. In contrast, flame-retardant cables are widely used in various settings to improve overall fire safety by preventing the spread of flames.

Both types of cables play essential roles in fire safety. The choice between flame-resistant and flame-retardant cables depends on the installation's specific requirements, including the need for circuit integrity during a fire and the overall fire prevention strategy of the building or installation.

Examples of flame-resistant and flame-retardant cables

Flame Resistant Cables

Power, communication, and control cables can be designed with fire resistant properties.

- Mineral insulated copper clad (MICC) cables consist of copper conductors inside a copper sheath, insulated with magnesium oxide powder. MICC cables are highly fire-resistant and can continue operating even in extreme fire conditions. They are often used in emergency lighting, fire alarm circuits, and public transport systems where maintaining power during a fire is critical.

- Fire-resistant Smoke Zero Halogen (FR-LSZH) cables are designed to ensure circuit integrity during a fire while minimizing the emission of toxic and corrosive gasses. They are typically used in areas with high population density, such as hospitals, schools, and commercial buildings, to facilitate evacuation and rescue operations.

- Ceramic-insulated Cables are used in extreme temperatures, where the insulation can turn into a ceramic form, maintaining circuit integrity even in direct fire. These cables suit nuclear power plants, industrial furnaces, and other high-temperature environments.

- Specific fiber optic cables are fire-resistant, according to NEC 770.

Flame Retardant Cables

- Polyvinyl Chloride (PVC) insulated cables are treated with flame retardant chemicals to prevent fire spread. These cables are widely used for power and lighting circuits in residential and commercial buildings.

- Low smoke zero halogen (LSZH) cables are made from materials that emit limited smoke and no halogen when exposed to high heat or fire. They are designed to inhibit the spread of flames and are used in enclosed public spaces like airports, train stations, and shopping malls where reducing smoke and toxic fume emission is critical for safety.

- Thermoplastic polyurethane (TPU) insulated cables can be formulated as flame retardant and used in various applications, including industrial and outdoor cabling. These are durable cables resistant to chemicals and oil.

- Plenum cables for plenum spaces in the building and riser cables for vertical runs between floors are flame-retardant.